Practical steps to extend the lifespan of mechanical systems

Extending the lifespan of mechanical systems requires consistent attention to maintenance, timely diagnostics, and thoughtful upgrades. This article summarizes practical measures—from inspections and corrosion control to battery care and telematics—that help vehicles and equipment operate reliably and reduce unplanned downtime.

Extending the lifespan of mechanical systems depends on predictable routines and informed interventions. Regular attention prevents small faults from becoming large failures, reduces emissions, and supports consistent performance. Whether managing a single vehicle, a fleet, or industrial equipment, combining inspections, maintenance protocols, diagnostic tools, and selective retrofits helps safeguard parts and systems while supporting long-term reliability.

Routine maintenance and inspections

Regular maintenance and scheduled inspections form the foundation of longevity. Follow manufacturer service intervals for oil changes, filter replacement, belt checks, and scheduled tune-ups. Inspections should include visual and operational checks for leaks, mounting hardware, and unusual noises. Documenting maintenance and inspection records supports pattern recognition—identifying recurring failures and informing preventive replacements instead of reactive fixes. Using local services for inspections can help address region-specific concerns like salt exposure or high humidity that affect corrosion rates and component wear.

Diagnostics and telematics for early detection

Advanced diagnostics and telematics allow early detection of faults and trends before they escalate. Onboard diagnostics, OBD readings, and telematics data streams can reveal misfires, sensor drift, or underperforming subsystems. Regularly review stored codes, performance logs, and fuel-efficiency trends to prioritize repairs. For fleets, telematics helps schedule maintenance based on actual usage rather than calendar time, reducing unnecessary interventions while catching units that need attention sooner.

Cooling, lubrication, and corrosion control

Maintaining proper cooling and lubrication directly affects component life. Keep coolant systems flushed at recommended intervals, monitor thermostat and radiator performance, and replace degraded hoses to prevent overheating. Use the correct grade of lubricants and change them at specified intervals to reduce wear on bearings and moving parts. Corrosion control—cleaning exposed metal, applying protective coatings, and addressing surface rust promptly—prevents structural deterioration that can compromise safety and lead to costly repairs.

Tires, brakes, and emissions checks

Tires and brakes are safety-critical and influence mechanical load and longevity. Maintain proper tire pressure, tread depth, and alignment to prevent uneven wear and reduce stress on suspension components. Inspect brake pads, rotors, and hydraulic systems frequently; addressing glazing, contamination, or worn pads early preserves braking components and calipers. Regular emissions checks and exhaust inspections detect leaks and inefficient combustion, which can indicate broader engine or fuel-system problems needing diagnostic attention.

Batteries, charging, and electrification considerations

Battery health and charging behavior are important for both conventional and electrified systems. For internal combustion vehicles, ensure alternator output and charging circuits function correctly to avoid repeated deep discharges that shorten battery life. For electrification and hybrid systems, follow manufacturer guidance for charging patterns, storage, and thermal management; battery cooling and state-of-charge management influence long-term capacity. When considering electrification retrofits, assess battery sizing, charging infrastructure, and the impact on existing systems to maintain safety and performance.

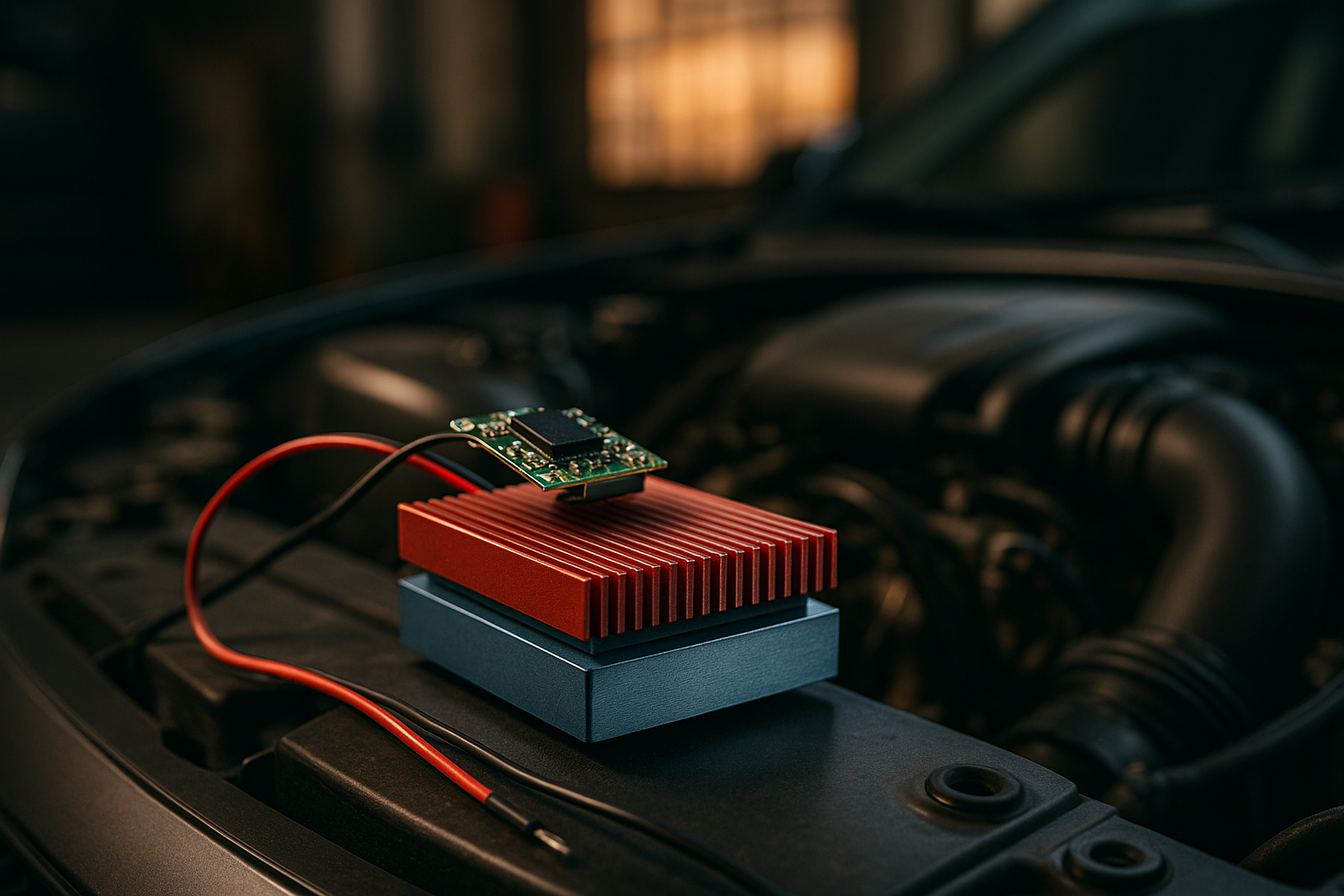

Retrofits, upgrades, and planning for longevity

Strategic retrofits and component upgrades can extend service life when original parts are obsolete or underperforming. Examples include upgrading cooling fans, installing improved corrosion-resistant fasteners, or fitting telematics modules for better diagnostics. Plan retrofits to maintain system compatibility and consider professional assessments for structural or powertrain changes. Document retrofit details and update maintenance plans accordingly to ensure that new components receive appropriate inspections, lubrication, and service intervals.

A practical program to extend mechanical lifespan blends routine maintenance, targeted diagnostics, corrosion and thermal management, and selective upgrades. Consistent inspections and good recordkeeping reveal early trends, while attention to tires, brakes, batteries, and lubrication prevents accelerated wear. Thoughtful use of telematics and careful planning for electrification or retrofits can further support reliable performance and reduce total lifecycle disruptions.